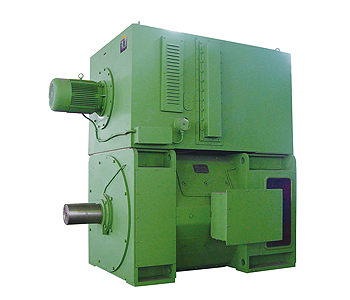

DC Motors

Royals Electric Direct Current Motors are optimally designed, engineered and manufactured for extra severe industrial duty applications, with state-of-the-art workmanship and premium grade materials and components, featuring superior reliability, ultra overload capacity, and excellent adaptability to driven equipment with wide speed change and huge impact.

Features

Compact and rugged frame with polygonal thin steel laminated structure and rigid integrity of stator parts and frame

Armature and commutator cores made of cold rolled silicon steel laminations with excellent permeability

Excellent commutating performance with specially designed types of armature windings and optimized commutator and brush stand

Strong Tungsten Inert Gas (TIG) welded commutator risers to the armature coils

Integrally constructed lifting device of commutator with unique design and workmanship to prevent effectively from breaking and welding failure

Extra reliable Vacuum Pressure Impregnated (VPI) insulation system

Premium quality grease lubricated cover type anti-friction bearings

Thermal detectors on windings and bearings, tacho or encoder installed on shaft to ensure maximum protection

Spacious and smart design on terminal box, inspection door and brush gear to ensure easy installation & maintenance

Technical Scope

IEC sizes from 100 to 1,250, 1.5 to 10,000kW

Armature Voltage: 160, 220, 330, 400, 440, 550, 600, 660, 700, 750V and higher

Field Voltage: 180, 220, 310V

Rated Speed: 200, 300, 400, 500, 600, 750, 1000, 1500, 3000rpm

Insulation Class F or H

Protection: IP21S, IP23, IP44 and higher

Cooling: IC06, IC17, IC37, IC81W, IC86W

Applications

Metals: rolling mills, flying shears, slitters, perforators, etc.

Pulp & Paper: pulp mills, paper machines, winders, reelers/coilers, etc

Cement: rotary kilns

Rubber & Plastics: extruders, internal mixers

Mining: diggers, excavators, coal mills

Cranes & Hoists

Sugar mills